PZS Engineering Sdn Bhd is now the appointed sole distributor for CERTUSS DAMPFAUTOMATEN Gmbh for Malaysia, Brunei, Thailand and Indonesia.

CERTUSS DAMPFAUTOMATEN Gmbh is currently the no. 1 leading manufacturer and market leader in the European Union. Since 1957, CERTUSS has produced steam generators / boilers whose design principles are based on the use of water tubes, making them compact, safe, and efficient. To date, the steam generators the company produces has been used in more than 800 locations around the world and is involved with over 80 different industries.

PZS Engineering Sdn Bhd is very excited about this opportunity and is proud to be associated with the CERTUSS family. We believe that the technology brought on by CERTUSS steam generators can revolutionise the boiler industry and also create new markets opportunities in Malaysia and Southeast Asia.

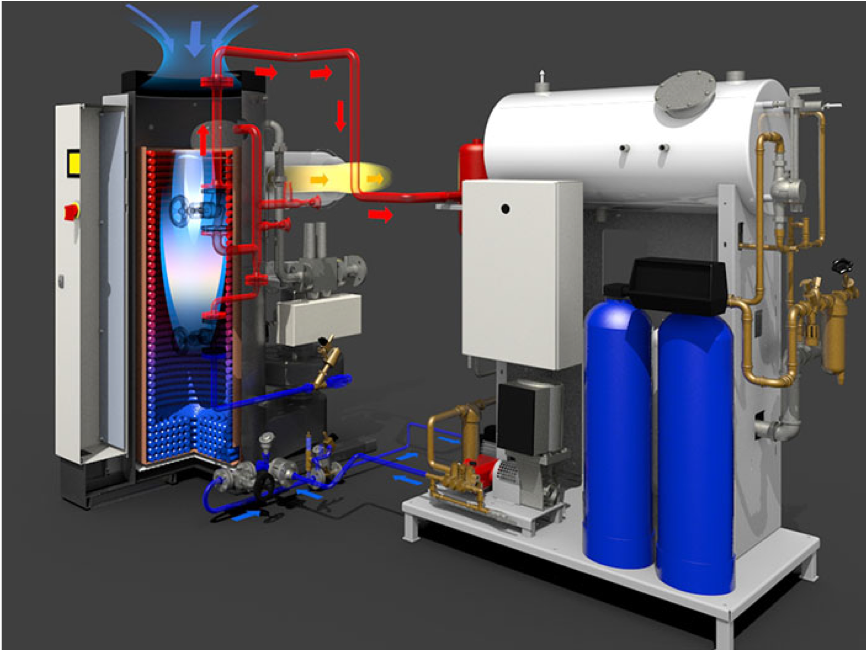

The functional principle

By using the water tube boiler principle, the CERTUSS technology for generating steam offers maximum safety, reliability and instant availability of high quality steam.

- The touch screen control panel simplifies operation and control of the generator. All configurations and settings of steam pressure are made here.

- The pre-heated feed water is delivered to the Generator at approx. 85°C to 96.11°C. The heat frees the oxygen from water and reduces the risk of oxygen corrosion.

- The heat exchanger coil is supplied with water through the feed water inlet. The change of phase from water to steam begins.

- The modulating, integral burner with the fastest response time, provides precise steam pressure control down to 0.01 BAR G.

- Insulation material is made obsolete by guiding the combustion air from the top of the Generator through an outer shell, and from there into an inner, secondary shell.

- The combustion air intake & fan draw in warm air through the triplex system to preheat the combustion air and keep the outer jacket cool.

- When the steam has been produced, it leaves the generator through the steam outlet and is then ready for use.

- The flue gas outlet connects to the chimney with or without an Economizer.

- Sediment is flushed out through the coil blow-down valve. The safety relief valve opens automatically to discharge excess steam when the pressure is too high.

Advantages of steam generators over conventional boilers

- Start-up time of 3-5 minutes with steam available

- Thermal Efficiency of up to 98% with CERTECON Economizer33

- Space saving

- No boiler housing required

- 92% to 94% thermal efficiency

- Reduction of piping costs due to decentralized plants

- Reduced corrosion due to vertical orientation

- Small ecological footprint

- Silent operation

- Anti vibration mountings preventing any vibration

- Operation without operator

- Delivery including CVE kit for an easy start

- Redundancy with multiple plant solution

- Less water & less hazardous potential

- Fully adjustable output of steam

- Ambient outside temperatur due to triplex shell cooling

- Predictive maintenance: informing of potential issues before they occur

- Fully automated

- Minimal and easy maintenance with spare parts available up to 20 years

- Around the clock aftersales support

- 7” Touchscreen display

- Remote access via Ethernet, Wifi or GSM

- Remote maintenance and control possible with iPad or iPhone

- Low emissions

- Less pollution through low water drainage

Product Range

UNIVERSAL TC

The Universal TC series is our most high performing steam solution. We offer various fuel types, including LPG, natural gas, #2 oil or a dual fuel burner for natural gas and #2 oil. The TC Generators are equipped to serve constant, as well as fluctuating, high steam demands. The touch screen control facilitates operation and gives a bundled overview of current pressures and configurations. All our Generators offer short heat up times and remote operation.

JUNIOR TC

The Junior TC series offers smaller sized Generators for customers who have a lower steam demand. We offer various fuel types, including LPG, natural gas and #2 oil. The TC Generators are our most space saving steam solutions. The touch screen control facilitates operation and gives a bundled overview of current pressures and configurations. All our Generators offer short heat up times and remote operation.

ELECTRO E 6 – 72 M

The CERTUSS Electro E 6 – 72 M Electric steam generator range, offers you the customer a wide choice of steam capacity, with 14 units available from 8 kg/h (6 kW) to 97 kg/h (72 kW) and operating pressures from 3.5 bar G to 11 bar G.

Steam output is controlled with semi-conductor contactors, offering a Modulation feature to meet any varying load requirements and optimising efficiency. This Electric steam boiler can be installed within production facilities and we can offer a full rear package assembly complete with water softener and blowdown vessel, which are pre- piped/ pre-wired and factory tested prior to dispatch to site. There is an output limitation feature available depending on the required volume capacity.

Access to all main function parts such as the stainless steel feed water tank, feed water pump, steam chamber and control panel is via the front enclosure doors, making maintenance of the unit simple to carry out. For remote monitoring, data can be transferred to BMS via Volt Free contacts. The CERTUSS E 6 M – E 72 M Electric steam generator is also available in full stainless steel construction for clean steam facility requirements to HTM 2031.

ELECTRO E 100 – 120 M

The CERTUSS Electro E 100 – 120 M Electric steam generator rapidly raises steam in < 3 minutes. With total heat output controlled by a pressure sensor and a 3 stage manual option output feature. The CERTUSS E 100 M – 120 M Electric steam generator is perfect for any small size steam industry user who have no fossil fuel available on site and therefore have a requirement for an electric steam boiler.

Installation can be carried out within production facilities and we can offer a full rear package assembly complete with water softener and blowdown vessel, which are pre-piped / pre-wired and factory tested prior to dispatch to site. The CERTUSS E 100 M – 120 M Electric steam generator is a compact, simple to operate unit, with electronic control. Data can be transferred to BMS via Volt Free contacts.

Steam output capacities are 135 kg/h (100 kW) and 160 kg/h (120 kW) with operating pressures available from 5 bar G to 10 bar G. Multiple units are available to meet higher or flexible demand requirements. Maintenance of the unit is simple, with a stainless steel feed tank, electronic level controller, water feed pump, steam chamber and control panel all integral of the main body framework.

The CERTUSS E 100 M – 120 M Electric steam generator is also available in full stainless steel construction for clean steam facility requirements to HTM 2031. All CERTUSS Steam Generators are manufactured to current PED 2014/68/EU standards.

CERTUSS STEAM PLANT

The CERTUSS Steam Plant CVE (CERTUSS Verified Equipment) supply unit combines all components needed to supply the Steam Generator in one compact body. Instead of having to combine many single elements our CVE offers all necessary add-on’s for supply and water treatment in one. Thereby complex on-site installations are redundant and factory-tested functional reliability is assured.

CERTUSS MODULAR PLANT

If your steam capacity or load requirements exceed a single generator output, CERTUSS can cater for your requirements by offering a CERTUSS Multiple Plant Solution. CERTUSS can supply many options to serve your steam demand requirements.

Be it a simple Duty-stand by facility or a flexible cascade system for the more complexed varying load requirements. With connection of the Generators to the CERTUSS Skid Mounted Package Plant Module (CVE), steam capacities up to 16,000 kg/h (6,560 kW) are available.

CERTUSS CONTAINER PLANT

The CERTUSS fully equipped container unit is our solution in case isolation from the rest of your plant is required. It contains all components necessary to operate an entire plant. After connecting the main services and commissioning, steam is at your disposal in less than 5 minutes. The self contained unit is flexible, allowing permanent, as well as temporary positioning. On inquiry we can take over full or partial installation of the steam system. If you choose to contract out to other companies, we can carry out consultation and supervision for your containerized unit.

CERTUSS CVE PLANT

- Ready-to-use water supply with CERTUSS package plant unit CVE.

- All supply and water treatment components for CERTUSS steam generators as complete unit.

- Less space required due to compact design.

- Professional installation ensures reliable and safe operation

- Corrosion protection by powder-coated base frame.

- Complete with electrical sub-distribution.

- Easy maintenance and access.

- Low-cost serial manufacture with optimally-coordinated components.

- Use of approved, high quality materials.

- Reduction in costs through considerable reduction in mounting time.

- Safe due to factory pre-installation of water, steam, electrical and power connections.

Installation can be carried out within production facilities and we can offer a full rear package assembly complete with water softener and blowdown vessel, which are pre-piped / pre-wired and factory tested prior to dispatch to site. The CERTUSS E 100 M – 120 M Electric steam generator is a compact, simple to operate unit, with electronic control. Data can be transferred to BMS via Volt Free contacts.

Steam output capacities are 135 kg/h (100 kW) and 160 kg/h (120 kW) with operating pressures available from 5 bar G to 10 bar G. Multiple units are available to meet higher or flexible demand requirements. Maintenance of the unit is simple, with a stainless steel feed tank, electronic level controller, water feed pump, steam chamber and control panel all integral of the main body framework.

The CERTUSS E 100 M – 120 M Electric steam generator is also available in full stainless steel construction for clean steam facility requirements to HTM 2031. All CERTUSS Steam Generators are manufactured to current PED 2014/68/EU standards.

Please contact us at [email protected] for more information on CERTUSS technology. Alternatively you can also visit our principal’s regional website at www.certuss-asia.com.